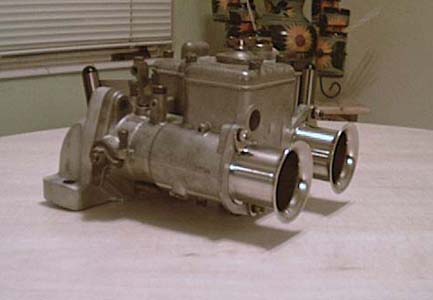

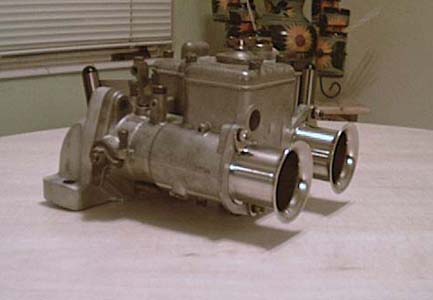

This is the 40DCOE mated with the intake manifold. Silly, isn't it? :o) Don't tell the wife that I put the carb on the kitchen table, I don't think she'll understand.

I rebuilt the carb and got new air horns for it. The original air horns were 'modified' by the PO by brazing on some wire mesh to serve as supports for a filter. At least that's my guess as to why a perfectly good pair of air horns were butchered the way they were. At first I wasn't planning on going through the carb prior to installation, but I decided to do it anyway and am now very glad I did. The throttle shaft bearings were very gummed up and sticky. The accelerator pump jets seals (O-rings) were crumbling and the fuel supply filter was clogged. I also found some shmutz in one of the idle jets. I had PBS jet it to make sure it will work well on an 850. Back in the good ol' days PBS sold a very similar kit for 850's, so they were able to jet it accordingly.

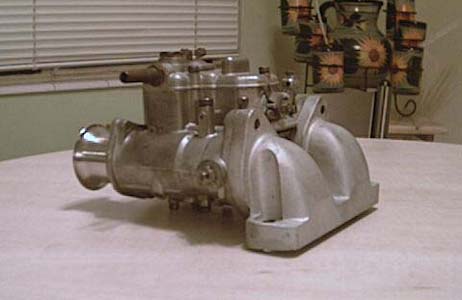

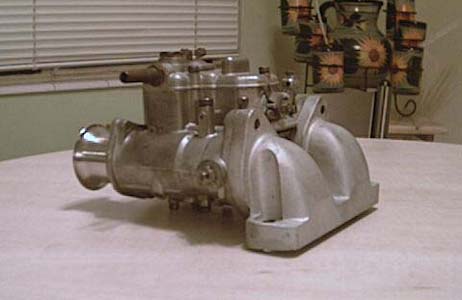

If you've already browsed my 850 Coupe Engine page you should be familiar with

the wild intake manifold and why it is the single most important part to getting

power out of an 850 motor. If not, click

here

and read all about it. This manifold follows the same design concept as you can

see below.

| Here's the manifold sitting on the head.

Note that as with the Coupe manifold, it's bolted in place using two of

the head bolts. As you can see, the intake hole in the head is severely opened up, so much so that two of the original manifold mounting studs are rendered useless. |

|

|

|

The two items that held up the project were the custom head bolts to mount the intake manifold and the radiator modifications to clear the carb. Many thanks to my buddy Courtney who came through with the custom head bolts. As you can see in the picture, the head bolts are 3/4" longer than the origial head bolts. The bolts were made by taking the standard 124 head bolts and turning them down to 9mm and threaded to a pitch of 1.25, this of course being the standard 850 head bolt threads. Note also that the heads have been machined down to 13mm. This is necessary to clear the intake manifold. With the standard 17mm head it was impossible to get a socket on the bolt. |

|

The other modification required is the change to a Sedan type radiator. The carb interferes with the radiator return line from the thermostat housing. The Sedans had the return spout coming out the top of the radiator as opposed to the rear. But that's not all, after trial fitting the carb I noticed that it ran right into the radiator itself! Rats. The Radiator was therefore moved forward

in it's mounting brackets to provide clearance for the carb. |

|

The cam that is now installed is a PBS 280ST. I was going to attempt to install it without removing the engine like Al Cosentino says, but decided it was not worth the hassle. I don't know how he claims it's easier than removing the engine. Heck, with the engine out it's enough of a pain in the ass, but I digress.

|

The final touches

involved making a throttle linkage. Funny how I didn't even think about

that little detail until after carb was fully installed. Click here for

the details on the linkage as well as

the exhaust system.

|

A CLOSE SHAVE -See the final fit issues

Back

to Lalo's Fiat 850 Page

Home

Home

©copyright V. Lalo Ruiz